Please contact our Mega Product Support or Mega Parts Sales for additional information or questions.

Contact Mega Product Support at the first indication of a warranty issue. Notifying Mega is required to initiate the warranty process.

Mega warrants equipment against defects in material and workmanship for a period of 12 months from the time the unit is first placed into service. Parts are covered for six months from the date of invoice.

Please provide the following:

You can send your forms and supporting documentation using any of the methods below.

Mega warrants its products and parts against defects in materials and workmanship. Please refer to Mega's Equipment Warranty Policy or Parts Warranty Policy for more detailed information or contact the Mega Warranty Administrator if you have any questions.

Please refer to our Parts Return Policy.

Please refer to our Parts Return Policy.

Please refer to our Parts Return Policy.

Yes. A restocking fee will be charged for returned parts not covered under warranty. Please refer to our Parts Return Policy.

Please contact Mega Parts Sales.

Mega is open Monday through Friday from 7am to 5pm (MT). For after hours or weekend service, please contact Mega Parts Sales.

Orders may or may not be cancelable. Please contact Mega Parts Sales for additional information.

Call 800.345.8889 with your customer purchase order number, order number or account number and we can provide a copy of your invoice. If you have a website account you can view previous invoices from the account management link.

Mega warrants parts against defects in materials and workmanship. Please refer to Mega's Parts Warranty Policy for more detailed information or contact the Mega Warranty Administrator if you have any questions.

Yes. Visit our Parts Technical Literature page to download our Mega Sourcebook.

SHV stands for “Spray Head Valve” and VSS means "Vertical Side Spray".

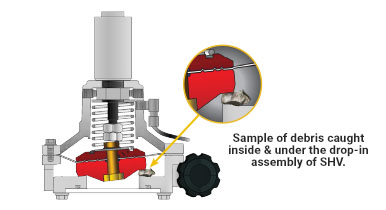

Mega spray heads have an adjustable ring that changes the flow rates and direction of the spray. Use this adjusting ring to control the intensity and geometry of your spray pattern. If that does not work, check the spray head assembly for debris and damage to the guide disc or lower housing. Contact Mega Product Support for assistance and more information.

The Mega pneumatic two inch SHV's have been discontinued. However, Mega offers an aluminum pneumatic three inch SHV P/N 300198 and a stainless steel pneumatic three inch SHV(P/N 052926). If a two inch valve is required, our Mega Parts Sales team can assist in providing the appropriate solution.

Yes. Current Mega water tanks can be upgraded to control more spray heads and butterfly valves. Contact Mega Product Support to determine compatibility. Please make sure to have your tank serial number available when contacting Mega.

Yes. Our complete stainless steel spray head valves are best suited to resist corrosion and abrasion caused by the harsh waters often found in mining and construction environments. Durability, low maintenance, and resistance to corrosion make Mega stainless steel spray head valves the ideal solution for demanding environments. Mega offers a hydraulic fully stainless spray head valve (P/N 047062) and a pneumatic fully stainless spray head valve (P/N 052926). Please contact Mega Parts Sales for more information.

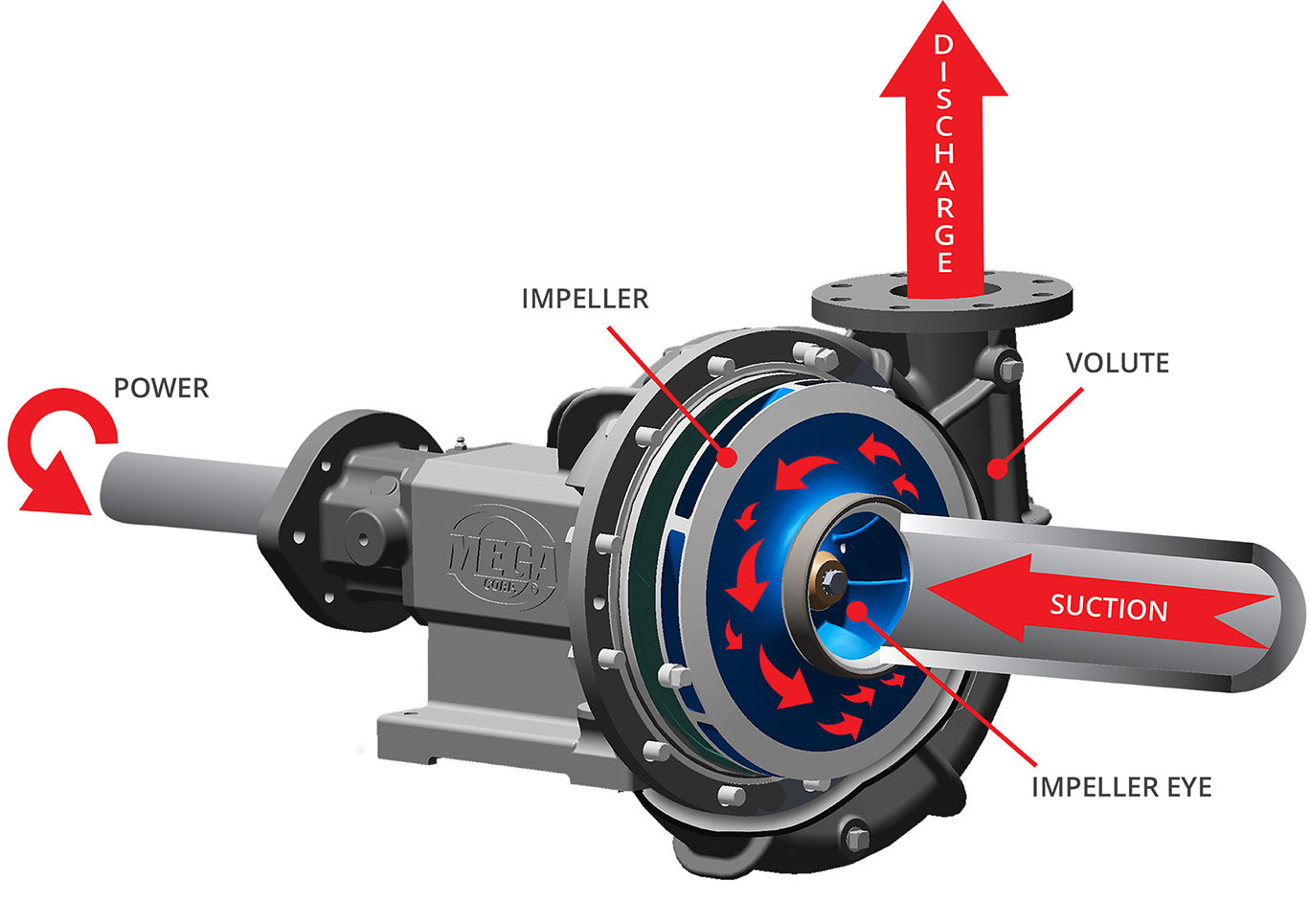

Centrifugal water pumps use centrifugal force to pressurize and move water from the inlet to the outlet. A rotating set of vanes (called an ‘impeller’) is spun by the pump shaft. As water is forced through the impeller, rotational energy is transferred from the impeller to the water, which gains velocity and pressure through the centrifugal force applied and is flung from the impeller. The volute (a spiral-shaped case) funnels the now-pressurized water to the outlet.

Pressure and flow are inversely related–that is, if pressure is increased, then flow decreases, and vice versa. "Pressure" is the amount of force per area, and "flow" is the volume of material moving through a given area per second (not the same as velocity, which is the distance traveled per time).

Water pressure is caused by resistance to flow. If a force tries to move water and there is resistance to that movement, then the water becomes pressurized. Consider a standard garden hose; when the end of the hose is unrestricted, water flows out of the hose in large quantities, but without much force. If you press your thumb over the opening, however, the stream of water that shoots out from around your thumb will be much more forceful and will travel further, but there will also be less water per second leaving the hose.

A centrifugal pump is ‘dead-headed’ when it is operated without an open discharge outlet (no water flow). In a no-flow condition very little horsepower input is required to spin the impeller, so the water pump drive motor input pressure will be low and the pump will not stall. Therefore, a dead-headed pump will convert the rotational energy of the shaft and impeller into heat. The heat will boil the water inside the volute, causing severe damage to grease and bearings.

Any time that the water pump is serviced and the gaskets are removed you should replace the gaskets. Gaskets are inexpensive and a faulty gasket will cause the pump to leak.

Yes. A small amount of water leaking through the shaft seal is necessary to lubricate and cool the rope packing and shaft sleeve. The recommended leakage rate is between 60 and 120 drops per minute, which will result in a small trickle of water. If water leakage is excessive, simply adjust the packing glands to compress the rope packing until leakage is within the recommended parameters.

Different types of packing are designed to leak at certain rates. If the packing begins to leak at a greater rate than the allowed amount, tighten the packing gland with a wrench until the leakage is reduced to within the specified parameters. Additionally, the stuffing box temperature should be checked regularly. If the temperature becomes too high, loosen the packing gland until the temperature drops to a consistently safe level.

Over time as the packing is subjected to continual heat and pressure through normal use, lubricant will be forced out of the packing material. The life of the packing material can be extended by periodically tightening the packing gland whenever there is packing leakage greater than the specified amount (Mega’s rope packing seals are designed to leak approximately 60 drops per minute). Eventually, all of the lubricant will have been squeezed out of the packing material, and tightening the packing gland will no longer prevent leakage. When this happens, it is time to replace the packing.

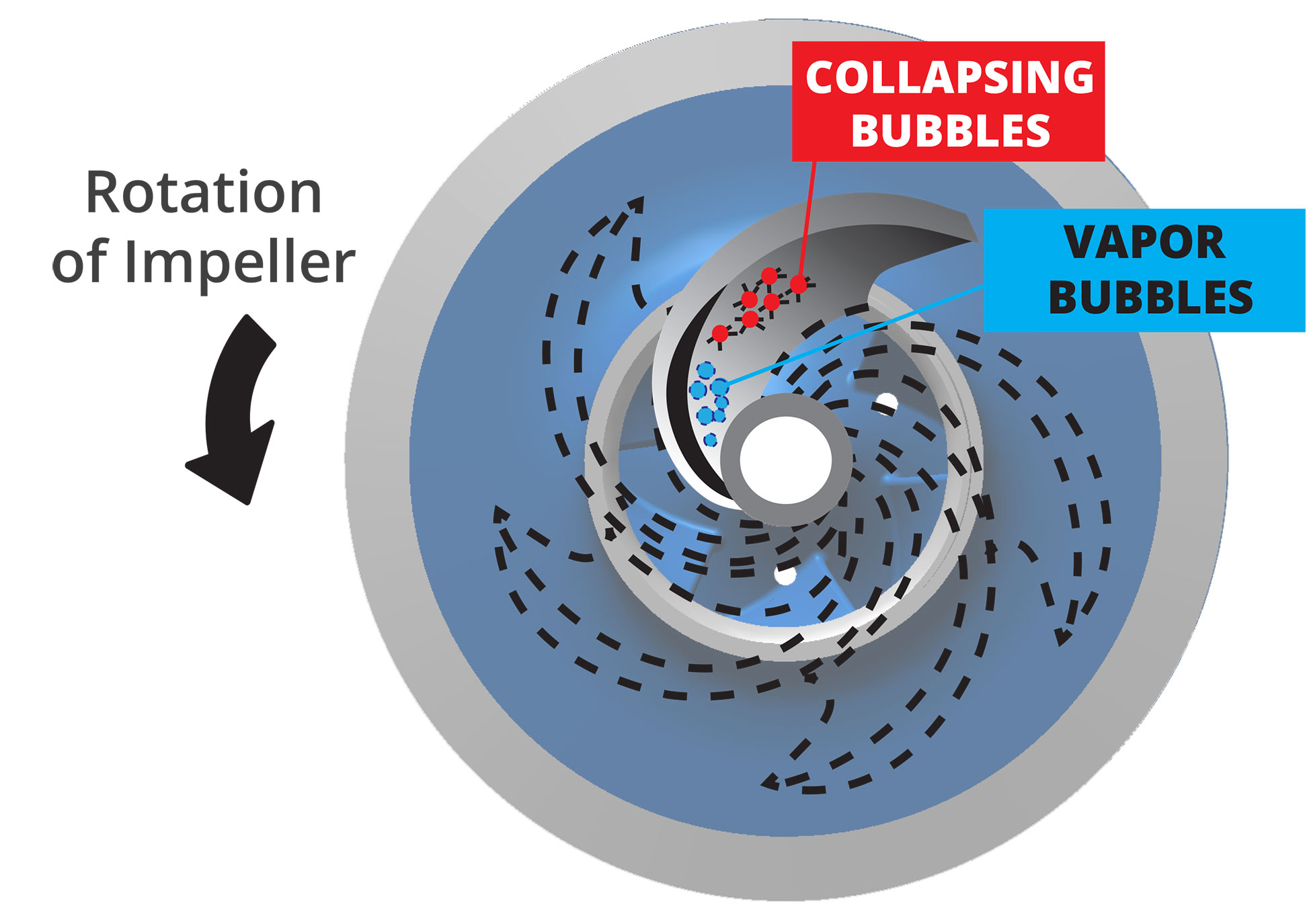

When the inlet pressure of a water pump falls below pump design specifications, tiny vapor bubbles can form in the water around the eye of the impeller. When the water containing these bubbles is forced into a high pressure environment on the other side of the impeller, these bubbles collapse, thereby creating tiny shock waves and points of high temperature. These shock waves can actually corrode the surface of the impeller. To prevent cavitation, always be sure to operate your water pump within its pressure and flow specifications.

No. The water pump shaft and impeller are rotating at high RPMs. Without water to transfer the heat created by rotational energy, the moving parts become extremely hot, causing severe damage to the pump and significantly limiting service life.

Good spray performance requires high water pressure. Some pumps are designed to move a high volume of water (high flow), and as a result the pressure of the moving water is low. In this case, try limiting the number of spray heads open at a time. Limiting the flow of water leaving the spray system should increase the water pressure. A water pump with high flow may perform poorly with four spray heads open simultaneously, but may work very well if only two spray heads are open. If the problem persists, check to see if the pump impeller or shaft bearings are worn or damaged.

There could be several factors causing this:

An air lock occurs when large pockets of air are drawn into the inlet side of the water pump. This creates a void and prevents the pump from drawing in water. This decreases, or can stop pump performance. If the air pocket is drawn through the impeller and into an area of high water pressure, the bubbles will collapse and create large shock waves that will severely damage the pump.

Water pump shaft failures can be caused by several factors:

Mega water pumps are constructed of cast carbon steel and 300 series stainless steel.

Yes, we do. Our Mega M4B water pump P/N 306201 is available in a corrosion-resistant form where all parts that come in contact with water are stainless steel. For the most corrosive environments, we offer a fully stainless steel Mega M4 water pump P/N 306647. Please contact Mega Parts Sales for more information.

Yes. Mega offers several different pumps with mechanical shaft seals.

Your pump should have a metal identification tag on the frame. If you cannot locate the tag, please send us a photo of your pump and we can help with identification. Contact Mega Product Support or Mega Parts Sales for assistance.

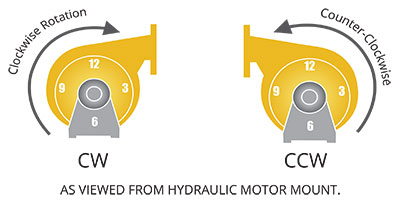

Water pumps rotate either clockwise or counter-clockwise as viewed from the drive shaft end of the pump. To determine rotation direction position the pump with the drive shaft end facing you. If the outlet of the pump is facing 90 degrees to the right, straight down on the right side of the pump center line, or straight up on the left side of the pump center line, then it is a clockwise rotation pump. If the outlet of the pump is facing 90 degrees to the left, straight down on the left of the pump center line, or straight up on the right side of the pump center line, it is a counter-clockwise pump.

Yes. If a pump is allowed to freeze with water in it, cracking of the volute case as well as damage to the shaft and bearings may occur. Thoroughly drain the water from your pump and tank in freezing weather. If the pump has been frozen, disassemble and inspect it for damage before returning it to service.

Exact intervals and grease amounts vary depending upon the type of water pump. Refer to Mega’s Schedule of Inspections Manual or the Mega Maintenance Manuals for exact instructions and details. Most Mega water pumps should be manually greased. The exception is Mega’s M4B pump, which can be greased with an auto-lube system or connected to a prime mover’s auto-lubing system. Over-greasing can damage bearings, and high pressure grease guns can blow out the pump’s grease seals, resulting in bearing failure. Refer to Mega’s Maintenance Manuals for full details.

While most water pumps are fairly quiet during operation, hydraulic drive motors can be quite noisy. Confirm that the noise you are hearing is coming from the water pump. If the pump is making a growling, grinding, squealing, or popping noise, it should be disassembled and inspected for damage.

Water pressure should be checked with water in the tank, spray heads closed, and the tractor engine at high idle. To obtain acceptable spray performance, a minimum of 85 psi water pressure under static conditions (no water flowing) is required. A static water pressure exceeding 125 psi can cause damage to water lines, connections and spray heads. Please refer to our Parts Technical Literature page for detailed information about your specific pump, or contact Mega Product Support for assistance.

Yes. Mega offers the following kits:

Some water cannon components are not included with the base kits. Please contact our Mega Parts Sales for additional information.

Mega offers a variety of high-quality nozzles for use with our water cannons. Please refer to the Water Cannons and Nozzles category in our Parts store or contact Mega Parts Sales for assistance.

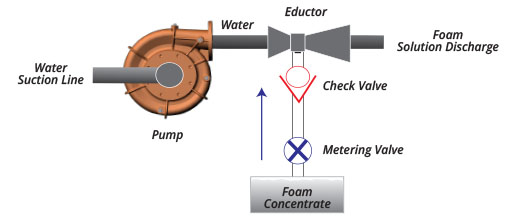

Mega’s foam fire suppression system is a foam eduction system. Pressurized water flows through a narrowed section waterway in the eductor (an air-aspirated nozzle) on the Mega water cannon. This creates an area of negative pressure that draws foam concentrate from a foam concentrate tank into the nozzle throat. The concentrate is mixed with water to create foam. Mega foam fire suppression systems can be used to address Class A and B fires.

Solid, combustible materials that are not metals are considered to be Class A fuels. Examples of Class A fuels are paper, wood, cloth, rubber, plastics and trash.

Class A foam is created by mixing Class A foam concentrate with water, creating a solution of bubbles that is effective at suppressing Class A fuel fires. This solution has a lower density than water and contains ‘wetting agents’ that reduce the surface tension of the water and increase its heat absorption potential. This allows the solution to penetrate and soak the burning fuel more quickly and efficiently than plain water. Class A foam is commonly said to “make water wetter”.

Combustible non-metal liquids are considered to be Class B fuels. Examples of Class B fuels are gasoline, oil, diesel fuel and grease.

Class B foam is created by mixing Class B foam concentrate with water to create a foam solution effective at suppressing Class B fuel fires. Instead of soaking into the burning fuel (Class B fuels are liquids), Class B foam forms a film or blanket on top of the fuel. This suffocates the fire by depriving it of oxygen. Class B foam should not be used for pressurized gas or three-dimensional Class B fires.

Pressurized gases are often stored as liquids, but become vapors at room temperature and atmospheric pressure. Class B foam solutions are designed to blanket flammable fuel and smother the fire, but the vapor pressure of pressurized gases is much too high for this to be possible.

Three-dimensional fires are Class B fires in which fuel is discharged from an elevated or pressurized source, creating a pool of combustible fuel on a lower surface. Because of the geometry of these fires, foam solutions cannot blanket the fuel to smother the fire.

No. Class A and Class B foams interact very differently with fuel, and they are most effective when used against their respective classes of fuel fires. Class A foam attracts carbon and reduces the surface tension of water, allowing it to penetrate fuels more easily. This is more effective on solid fuels than on liquid fuels. Class B foam repels carbon and forms a film on top of the fuel instead of soaking in, making it very effective at smothering liquid fuels. It is highly recommended for mining and construction sites to have both Class A and Class B foam on hand.

No. Class C fires are electrical fires. Water is an excellent conductor of electricity, therefore it is extremely dangerous to use water or water-based foam to combat Class C fires . Class D fires involve combustible metals such as magnesium, sodium, and potassium. These metals are highly reactive with water and water-based foam should not be used to suppress Class D fires.

Always refer to the foam concentrate manufacturer’s specifications and recommendations for storage. Mega’s foam concentrate tank is made with 300 series grade stainless steel

Please contact Mega Parts Sales for a custom configuration for you application. Contact Mega Product Support for chassis integration solutions.

Mega provides upgrade solutions for both digital and analog spray control systems.

A new pedestal mount may be required with both kits. Some customer labor is required for installation of these kits.

Mega offers several optional features that enhance the value of our spray control systems.